Hazardous Substance Analysis Lab

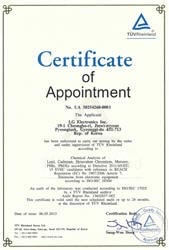

LG Electronics has been operating the precision analysis accredited environmental testing lab for hazardous substances, which is equipped with ICP-OES, ICP-MS, GC-MS, UV-Vis, HPLC, VOC chamber and IC. The lab has been supporting hazardous substances reduction and verification of greener products via testing for high-risk materials and inspecting parts and products for compliance with internal limits on hazardous substances. It was designated as an authorized testing lab for 4 EU RoHS hazardous substances by UL (Underwriters Laboratories) in 2005, and designated as an authorized testing lab for six hazardous substances (RoHS) by Germany’s TÜV Rhineland in 2006. In 2009, the lab was accredited by TÜV Rheinland for analysis of 15 high risk substances (SVHC) which were added to the EU REACH Regulation (Registration, Evaluation, Authorization & Restriction of Chemicals) at the end of 2008 ; the lab was also accredited to test for volatile organic compounds (VOCs) that could be emitted when using electronics.

The lab was also recognized as an ISO 17025 certified testing lab for EU RoHS six hazardous substances and phthalates for which the lab’s analytical capability was recognized as meeting the international standard requirements.