Absorption Heat Pump

LG Provides incredible cooling solutions for your business, discover how the Energy Saving Absorption Heat Pumps will keep your business cool. Learn about the product features below.

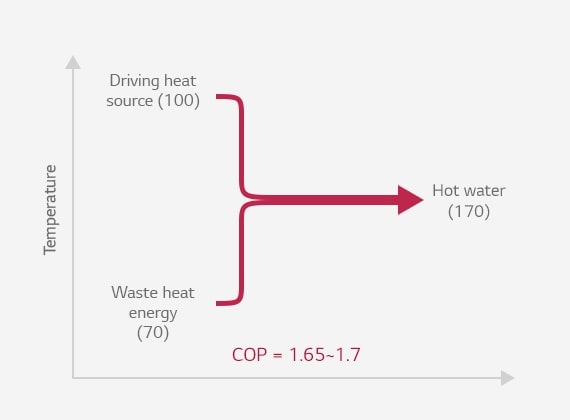

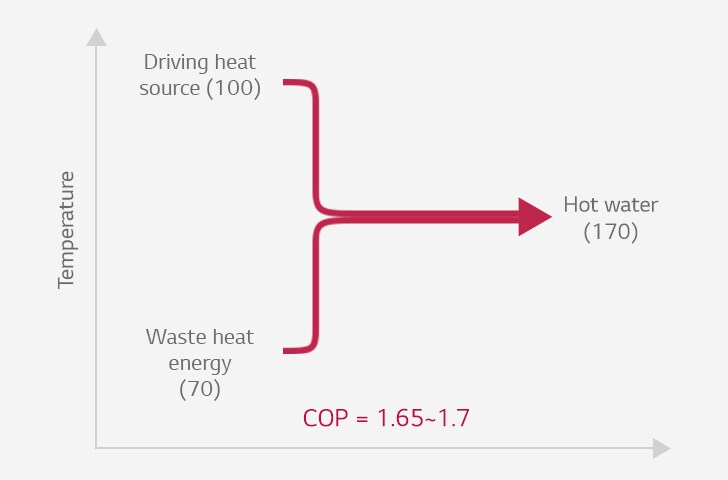

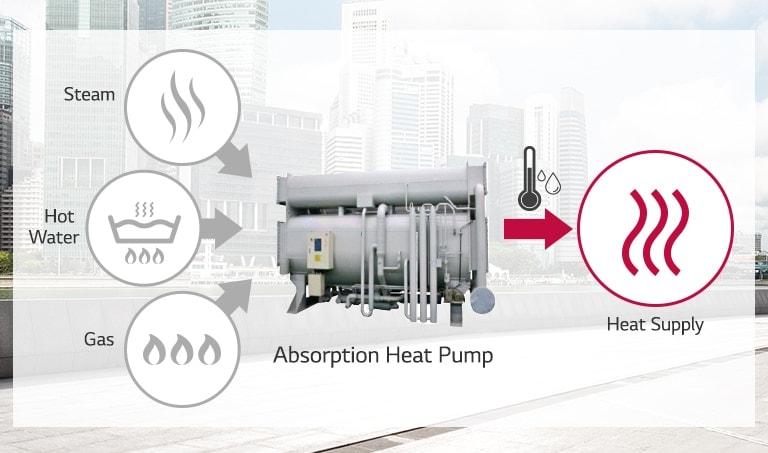

Utilizing Unused Energy as Heat Source

It supplies high temperature water up to 80℃ by using 70-80% of unused energy such as waste heat source, river water and ground water discharged from power plants and sewage treatment plants. It can save energy economically because it draws low temperature heat energy to high temperature heat energy with small amount of energy.

-

![Graph shows two lines, top for driving heat source, bottom for waste heat energy, merging in the middle, symbolizing hot water.]()

![Graph shows two lines, top for driving heat source, bottom for waste heat energy, merging in the middle, symbolizing hot water.]()

The First-class Absorption Heat Pump

This system produces medium-temperature energy by using operating high-temperature energy and low-temperature waste heat energy. It is an economic option as it reduces the heating amount by absorbing heat from the low temperature heat sources to be utilized in mid-temperature. -

![Central line in graph, representing waste heat energy, splits into top (driving heat source) and bottom (waste heat energy) directions.]()

![Central line in graph, representing waste heat energy, splits into top (driving heat source) and bottom (waste heat energy) directions.]()

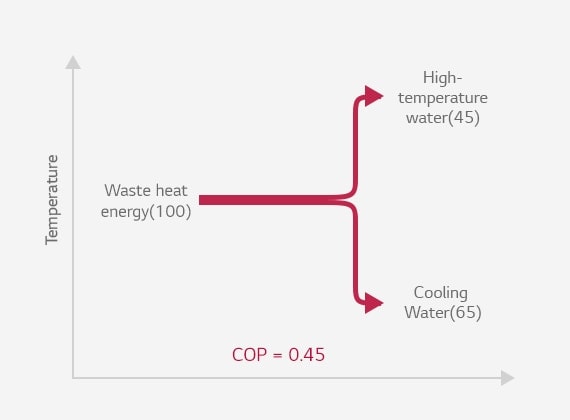

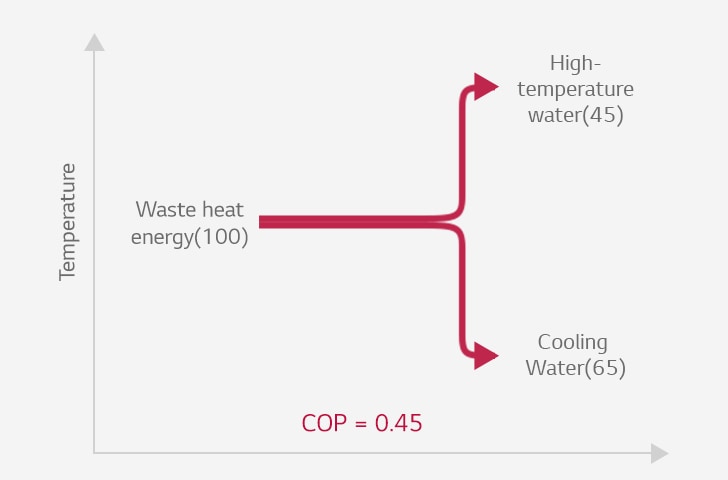

The Second-class Absorption Heat Pump

This system produces high-temperature and low-temperature energy by using waste heat energy of medium temperature. When the heat is supplied at the mid-temperature, it is converted into high temperature and low temperature, which is a very useful method for recovering industrial waste heat.

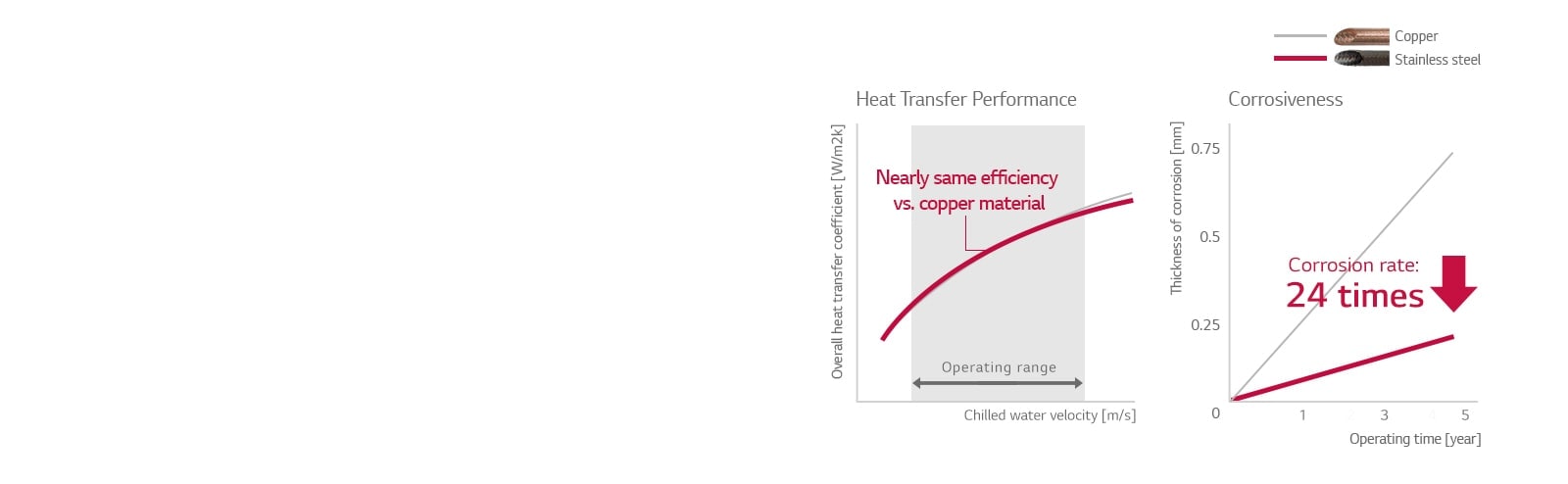

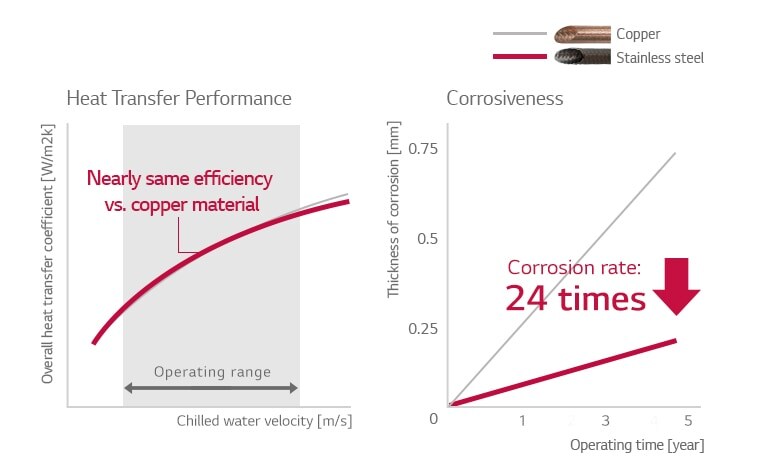

High Performance Stainless Steel Tube

Specially manufactured stainless steel heat pipe with LG's exclusive technology has the same heat transfer performance as copper pipe and has very high corrosion resistance compared to copper pipes, ensuring stable heat transfer performance even for long time operation.

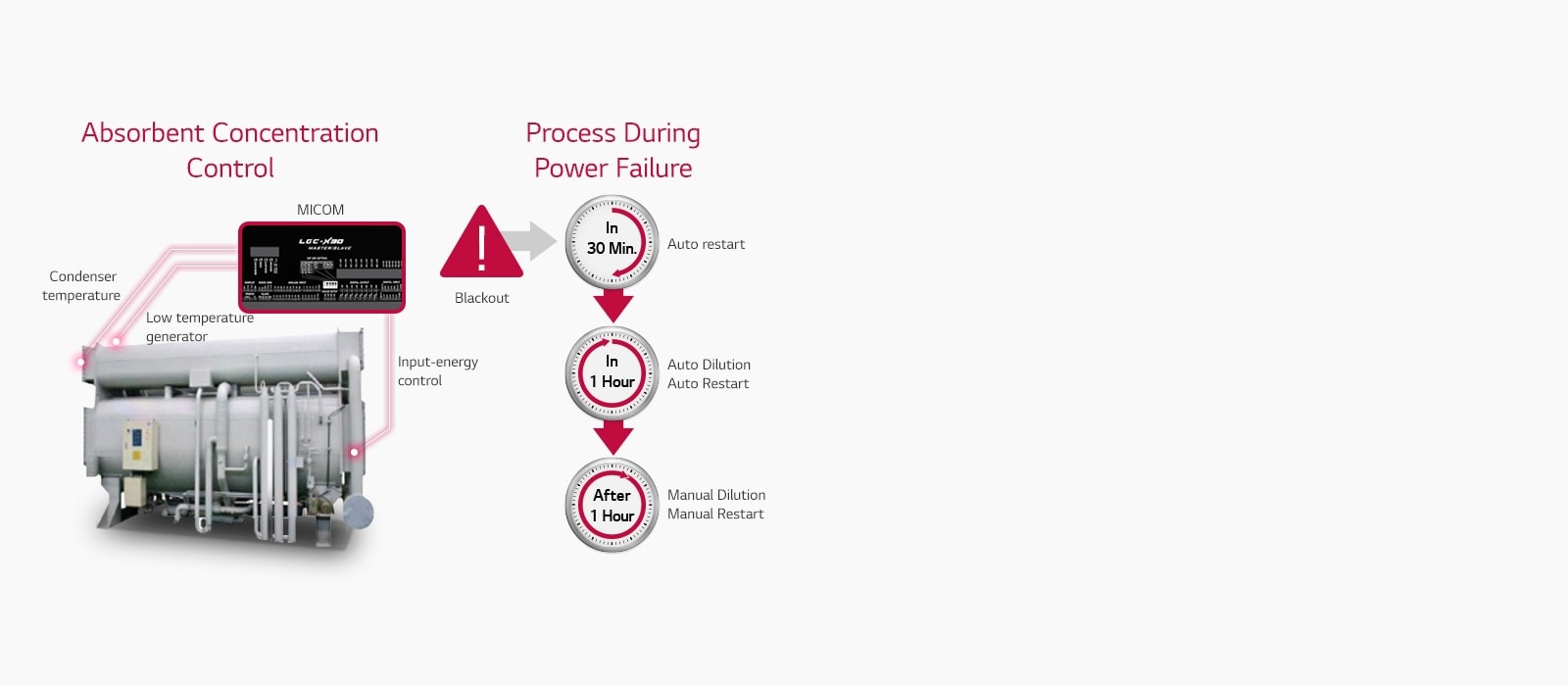

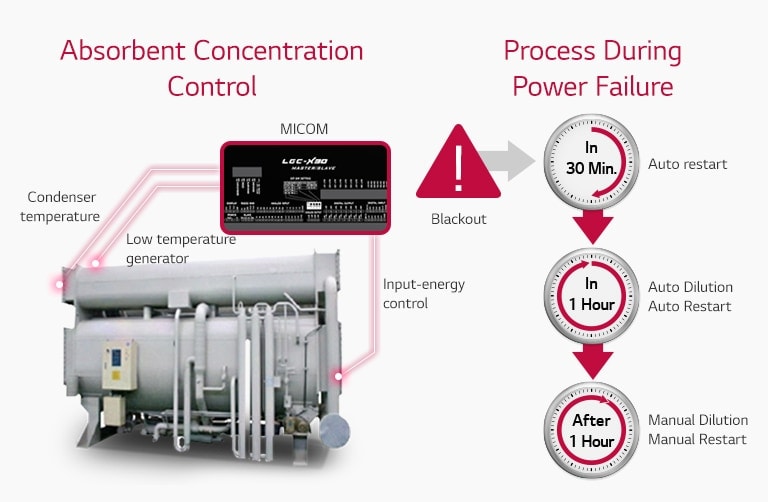

Absorbent Concentration Control & Prevention

The absorbent concentration is calculated by the built-in crystal control protection logic and the prevention control is executed when concentration rises above the set value. With automatic control, it prevents pre-absorption of liquid crystals and calculates the time from power failure to complete recovery through the independent timer.

-

![3 small circles are arranged in a triangular pattern on the outline of a larger circle. Each small circle features a 3-part partition at its center.]()

Superior Installation Convenience

3 Parts Partition enables easy installation at narrow places such as remodeling & renovation sites.

-

![Front view of the LG absorption unit, two dotted-outline rectangles with red arrows suggest that these components can be opened.]()

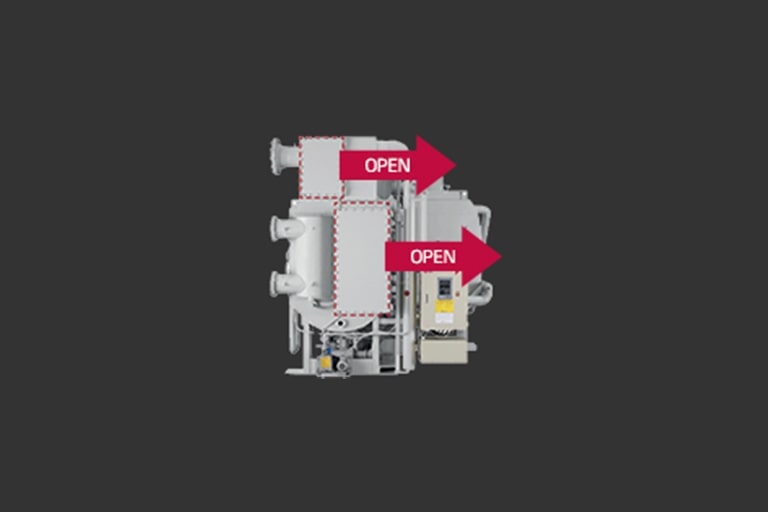

Easy Pipe Cleaning

When cleaning the piping, only the water box cover can be opened without disconnecting the piping.

-

![The rectangular control panel is central, with a vacuum pressure transmitter connected to a red dot on the left, and an X30 controller on the right.]()

![The rectangular control panel is central, with a vacuum pressure transmitter connected to a red dot on the left, and an X30 controller on the right.]()

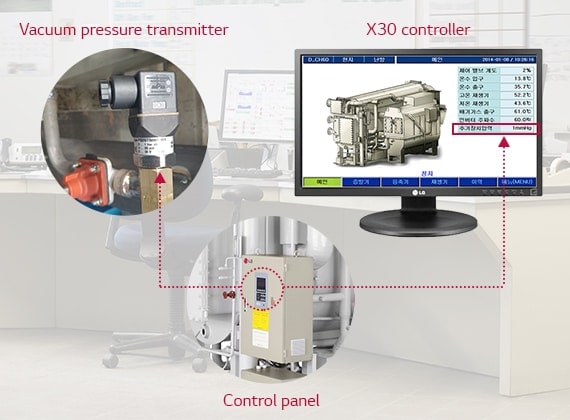

Digital Pressure Check

Digital pressure gauge is used to monitor the pressure inside the refrigerator in real time. The vacuum rate is automatically set and saved. The saved data can be used to accurately and quickly monitor and diagnose leakage. -

![A person holds a tablet displaying a control solution. Four red lines extend from the tablet, connecting to buildings on the left.]()

![A person holds a tablet displaying a control solution. Four red lines extend from the tablet, connecting to buildings on the left.]()

Optimized Central Control

Control solutions such as ACP IV and AC Smart enable easy monitoring and allow remote control to manage various HVAC models at anywhere.

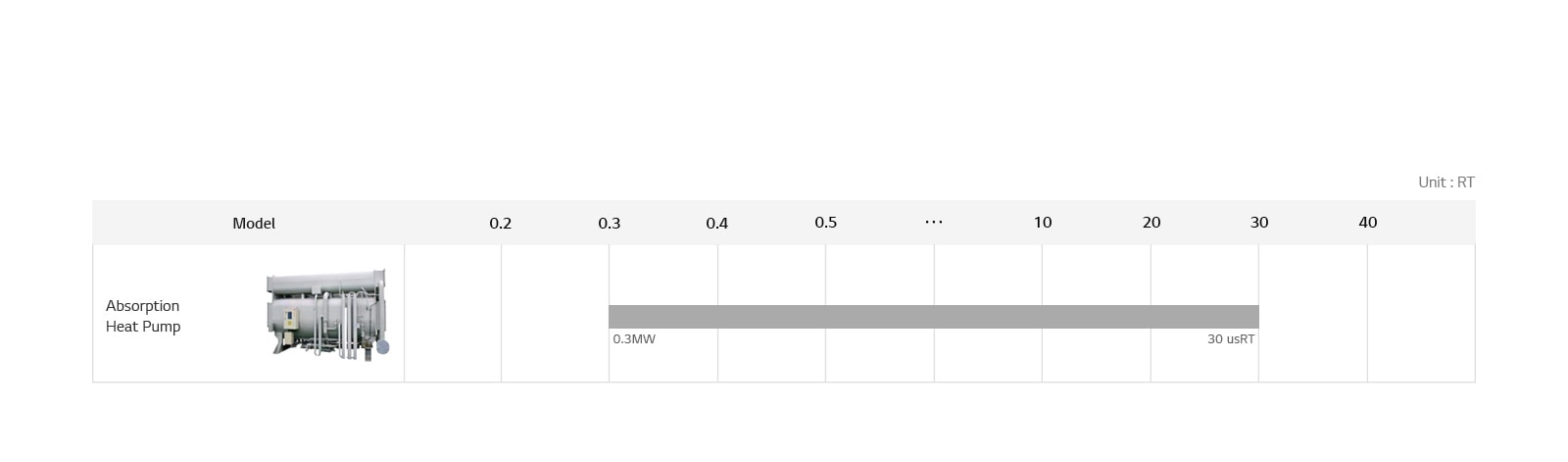

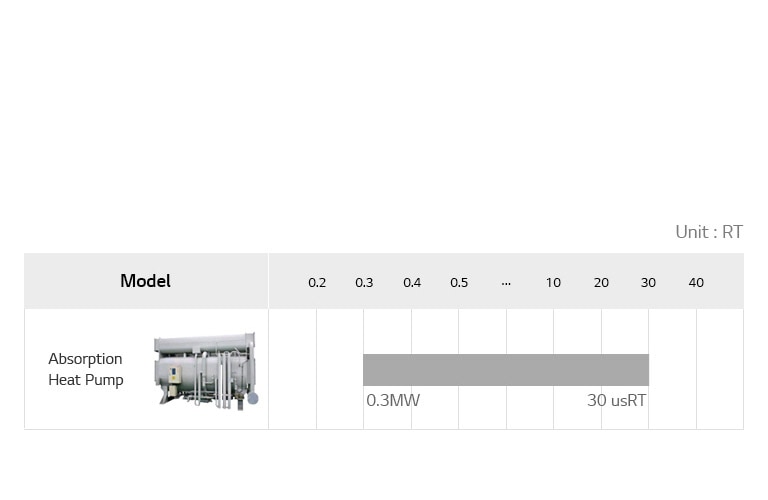

Absorption Heat Pump Line Up

Contact Us

Please contact us for more information on the product and we will get in touch with you soon.