We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

Make it sustainable

everyday

If you love it, look after it.

We create products that make

living sustainably, and cherishing

the life we love, part of our everyday.

Steps towards a sustainable living

-

Water saving

Save water

to turn the tideAlmost 10% of global freshwater consumption is residential water usage.*

Here are some innovative ways to help you save water and preserve this

precious resource.

-

Energy saving

Save energy

Secure our futureAs home appliances become increasingly advanced, their energy

consumption also increases. To live more sustainably, choose

environmentally-certified, energy-efficient products that reduce energy

consumption and meet energy-saving standards.

-

Water savingSmart tech

water efficiency -

- LG washing machines and dishwashers with water-saving technology reduce water usage without sacrificing performance.

-

Worried your washing machine uses too much water?

- Despite getting clothes clean, some washing machines consume an excessive amount of water. This, however, can be solved by LG washers featuring the Artificial Intelligence Direct Drive™ (AI DD™), which suggest the optimal wash cycle for each load by detecting the weight and fabric softness of clothing.* They also employ LG’s own TurboWash™ 360 technology, which uses a 3D ‘multi-nozzle’ that sprays water in four different directions simultaneously. The result is clean clothes, shorter cycle lengths and less water usage without any sacrifice to washing performance whatsoever.**

-

- Additionally, our latest washers come with ezDispense™, a clever feature that automatically dispenses the optimal amount of detergent needed for the load being washed. It boosts washing efficiency by reducing the number of rinses needed per-cycle. ENERGY STAR-labelled products that help consumers save money while helping the planet, the company’s latest washers use 25 percent less energy and 33 percent less water than conventional models.***

-

-

- *Average water consumption reduced by approximately by 10.6 percent with AI DD™ when tested by Intertek in April 2020 on Cotton cycle with load comprising 3kg of underwear in conventional LG washer model F21VDT and LG AI DD washer model W16SK. Results may differ depending on product models and actual usage environment.

- **Tested by Intertek in April 2020 on Normal cycle with TurboWash 360(TURBOSHOT) activated with load comprising 3kg of laundry. LG TurboWash 360 model W16SK uses approximately 36 percent less water and shortens cycle length by 46 percent compared to the same model with same load size set to Normal cycle without TurboWash 360(TURBOSHOT) selected. The product models and results may differ depending on regions and actual usage environment.

- ***https://www.energystar.gov/products/clothes_washers

-

Worried your dishwasher uses more water than handwashing?

- As well as providing greater convenience in the kitchen, a dishwasher can also deliver efficient water usage.* Through precise control of water circulation and spray intensity, ENERGY STAR-certified dishwashers cost only USD 35 per-year to run and save on average 3,870 gallons of water over their lifetime.**

-

- Much like the company’s washing machines, the LG dishwasher uses less water without compromising cleaning performance. LG’s QuadWash™ technology has Multi-Motion spray arms that rotate back and forth to separate food and oil from dishware, while TrueSteam™ helps to reduce the occurrence of water spots, leaving dishware sparkling clean.***

-

-

- * “A European Comparison of Cleaning Dishes by Hand.” University of Bonn, 2007.

- **https://www.energystar.gov/products/dishwashers

- ***Tested by LG internal lab on Normal Cycle with clear cup of glass in LG non-Steam model DFB415 and LG Steam model (DFB325), according to LG internal test methods.

-

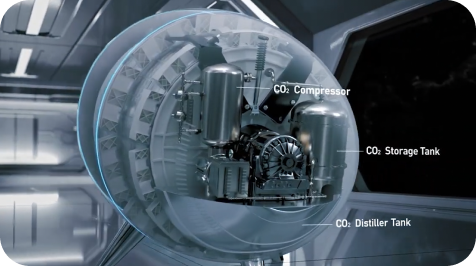

Waterless washingWashing without water

- We're developing breakthrough technology that will be able to wash clothes using pure CO2, without using a single drop of water. This washing machine compresses carbon dioxide and uses it as a laundry solvent to wash laundries. It vaporizes and re-collects carbon dioxide after washing and reuses it for the next wash. Our technology keeps moving forward to help you save water and conserve precious resources.

-

-

- *All scenarios are fictionalized and simulated. For illustrative purposes only, not for sale as of 2023.

-

Energy savingHigher energy

efficiency,

lower carbon

impact -

- Our individual efforts combine to make a huge, positive impact. By choosing energy-efficient products and reducing our overall energy usage, we can create a more sustainable future.

-

LG InstaView™What’s energy-efficient about knocking twice to see inside?

-

Ask yourself this: how many times do you open your refrigerator without taking anything out? We’re all guilty of opening the fridge door out of curiosity or to check what needs replenishing and this has a significant impact on how much energy you use.

With the LG InstaView Door-in-Door refrigerator, there’s absolutely no need to open the door all the time – with its sleek mirrored glass panel, just two quick knocks provide easy access to view the contents of the fridge by illuminating the glass to see inside without opening the door, saving energy and time. -

- This not only means that it will keep your food fresh for longer (up to 41%* less cold air loss), but is also energy efficient (up to 32%** less energy consumption).

-

-

*41%

Based on Intertek testing of models SX5534WB, GR-S632GLRC, and LFX31945ST/02 in accordance with LG internal testing methodology measuring percentage reduction in exchange rate of air when opening Door-in-Door™ compared to the refrigerator door for 10 seconds. Results may vary by models and duration of door opening. -

**32%

Compared to the refrigerator with LG conventional reciprocating compressor. Based on VDE testing comparing energy consumption between LG model GBB530NSCXE and GBB530NSQWB. Energy consumption test based on ISO 15502 standard.

-

*41%

-

ENERGY STAR

certificationHow much energy can certified products save? -

Our unwavering commitment to energy efficiency has been recognized with the prestigious ENERGY STAR Award. The ENERGY STAR Award given by the U.S. Environmental Protection Agency and the Department of Energy are presented to businesses and organizations to confirm their outstanding contributions to protecting the environment through superior energy efficiency achievements annually since 1993.

We have been selected for the Award 10 times from 2012 to June 2023. LG Electronics ENERGY STAR-certified products have reduced 3.7 million tons of GHG emissions during their lifetime. For reference, 3.7 million tonnes of GHG are equivalent to the total GHG emitted by 702,770 cars. -

-

Smart home technologyEnergy saving made simple

- Making your home more energy-efficient is a breeze with the LG ThinQ app and its smart sustainability features. These features make it easy for you to improve the energy efficiency of your appliances effortlessly. The app even pays attention to how you use these appliances. For instance, it can reduce the refrigerator's power usage during nighttime hours when you're less likely to open and close the fridge frequently. An unexpected bonus is that you can see exactly how much energy you save by using these energy-efficient practices. With the ThinQ app, you'll also get a better understanding of how your household gadgets are used each month.

-

-

- *LG ThinQ App compatible products, services and available features may vary depending on model or region/country.

Sustainable materials

Conserving resources

matters to us

Earth's resources are limited, so conserving resources is no

longer optional. By reducing material usage or choosing

renewable or recycled materials, we can all live a more

sustainable life.

- *Materials certified by UL 2809 Environmental Claim Validation Procedure (ECVP) for recycled content applies to 2022 LG Soundbar models S95QR, S90QY, S80QR, S80QY, S75Q, S65Q, S60Q, S40Q, SH7Q, SPQ8-S. Amount of recycled fabric varies by model and LG Soundbar models, which come with polyester jersey fabric made from recyled material that meets Global Recycled Standard, are S95QR, S90QY, S80QR, S80QY, S65Q, S60Q, S40Q, SH7Q.

- **The Environmental Claim Validation certification pertains solely to the TONE Free product and does not cover additional accessories. UL ECV applies to UT60Q, UT90Q, UTF7Q, and xx.

Our commitments to the planet

-

Carbon neutrality

-

Circularity

-

Clean technology

Use smart.

Live sustainable.

Your sustainable living journey truly inspires us.

We're committed to both promoting sustainable living

and empowering you along the way.