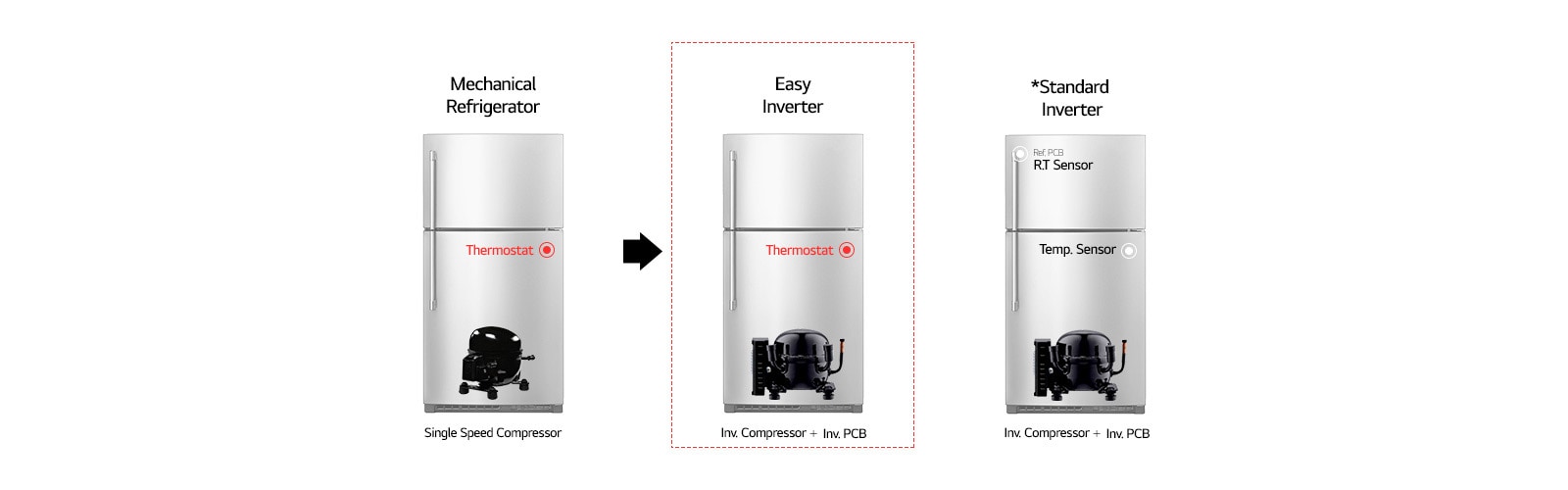

The major difference between an inverter compressor and a normal one is the speed. In a normal compressor, the speed is fixed, whereas in an inverter compressor, the speed is variable, that is why it is also known as a variable speed compressor.

In the case of a fixed compressor, the speed remains fixed, consuming a fixed amount of energy regardless of the system requirement, which means the system would consume a fixed amount of energy, without being able to regulate its energy consumption, regardless of the ambient temperature. In contrast to this, in an inverter refrigerator, the compressor’s speed fluctuates depending on the ambient temperature. Inverter compressors have a variable frequency drive, commonly known as VFD, which helps in adjusting the speed.

The ability to adjust speed implies that they do not always have to work their hardest to perform at peak load conditions, unlike fixed-speed refrigerator compressors. For the same reason, they are more durable and longer-lasting than non-inverter refrigerator compressors.

Conventional refrigerator compressors run at peak load conditions even in low ambient temperatures prompting more wear and tear as a result of overwork, indicating a higher power consumption as opposed to their inverter counterparts.