I have worked for LG Compressor R&D for over 20 years. The product development project I participated in was involved in the development of most of the rotary products that are currently being mass-produced. I can't list them all, but two memorable ones come to mind. The first one is a single compressor that can replace a modulation system with two compressors that existed in the Korean domestic market, and the second one is the window-type compressor mainly used in North America. I remember that both encounters were not easy as both were developments that had to increase their performances and efficiencies to their maximum capacity.

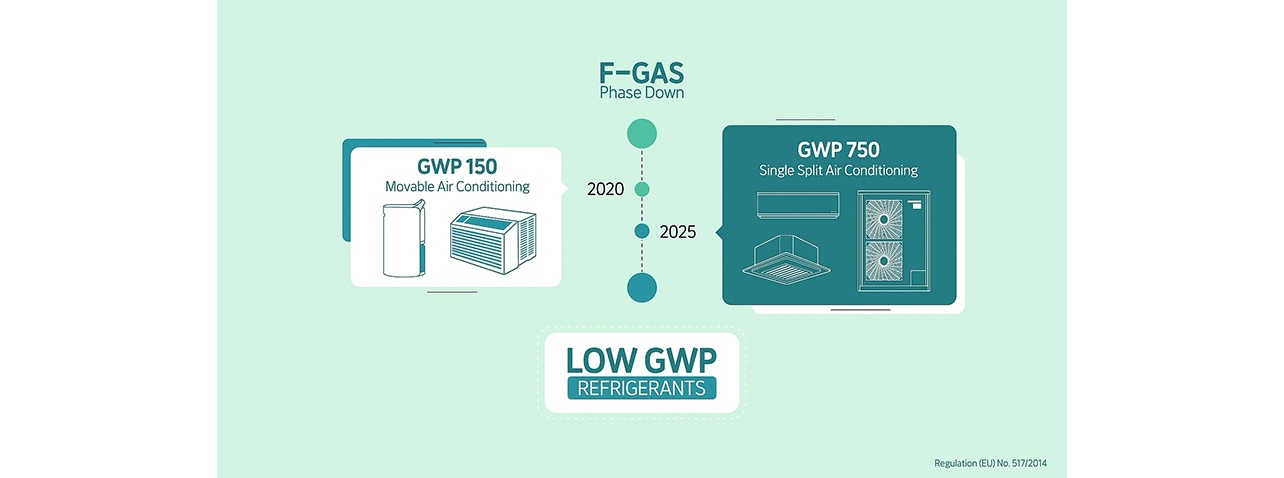

Another special memory that I can remember clear as day was the development of an air conditioner compressor for a camping vehicle and not for general residential use. Because of its different standards and different environmental use, it required a different evaluation and verification than the previous models. Despite these different challenges, we have successfully applied different systems even in different circumstances. In a recent case, the development of the R290 compressor, in response to the low GWP, has caused major issues. Therefore, the existing R290 lineups are being further reinforced to meet the market demands.