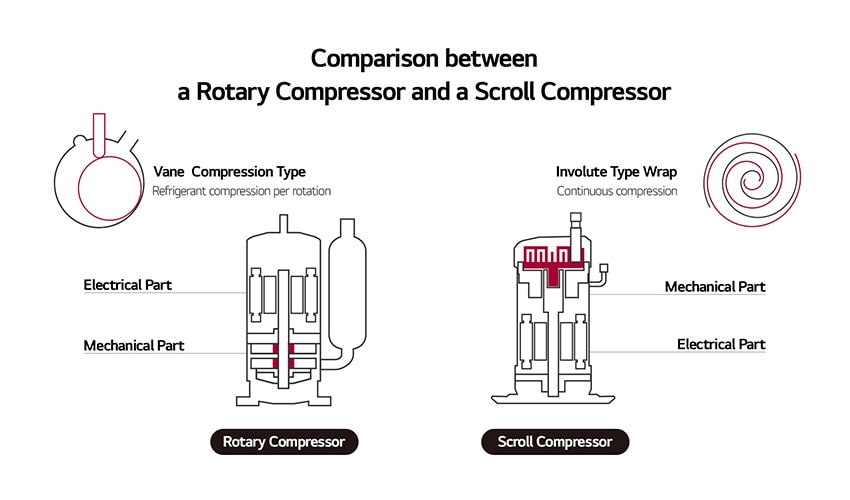

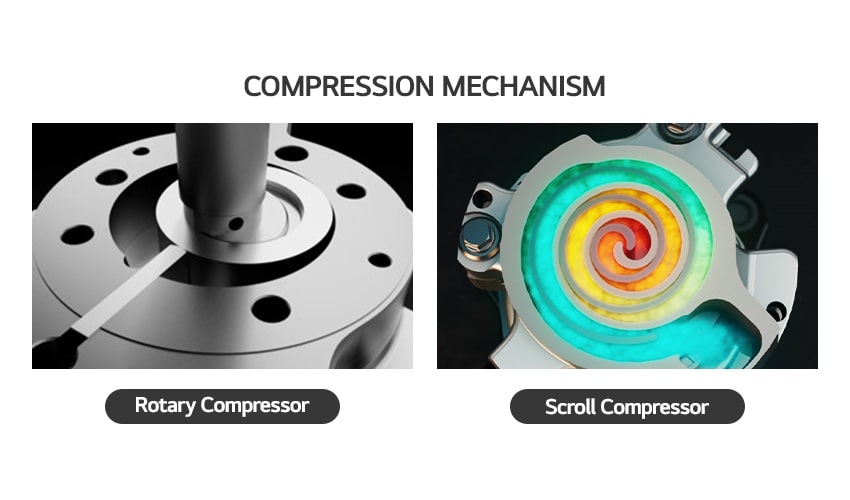

Scroll and rotary compressors are built differently and that is why they operate differently. The key difference between both compressors is their mechanical structure and design.

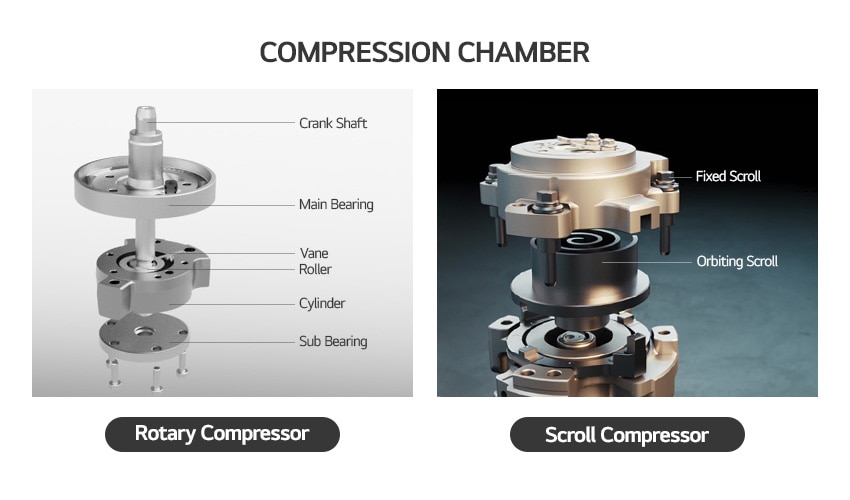

A rotary compressor’s compression chamber is located at the bottom of the compressor, whereas in a scroll compressor, it is located at the top.

A scroll compressor can further be divided into smaller subcomponents such as a fixed scroll, an orbiting scroll, a motor, bypass valves, a thermal protector, an internal pressure relief valve, a discharge check valve, an overload protector, etc.

Components such as a thermal protector, internal pressure relief valve, discharge check valve, and overload protector protect the compressor from potential damage.

On the other hand, a rotary compressor consists of a cylinder, an accumulator, a main bearing and a sub-bearing, a crank shaft, a roller, and a vane.

It can easily be observed that a rotary and a scroll compressor do not share any components except for a motor. The biggest difference between a scroll and a rotary compressor is the mechanical structure.